shot pala today and tested some,

first up was the dasher, i had never done load development for it because it just shot good with the first load i tried and i had been neglecting it to be honest sorry miss dasher

sorry miss dasher

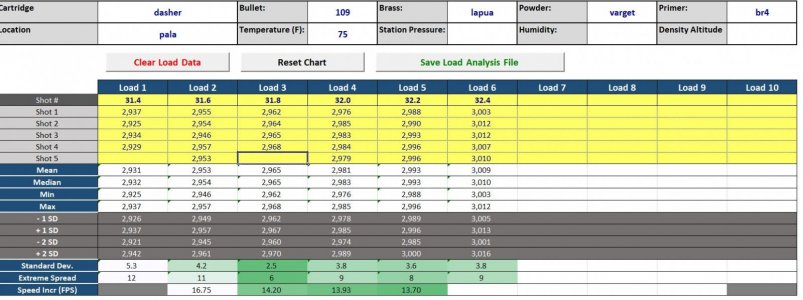

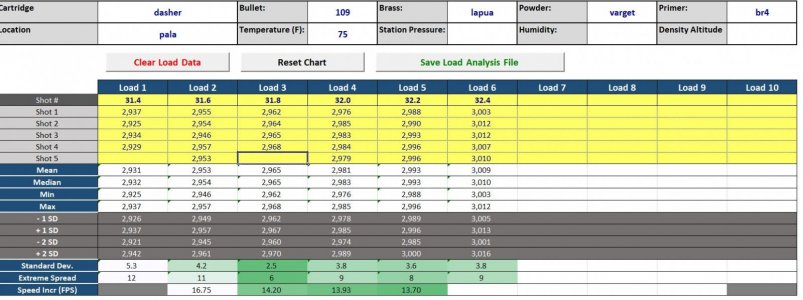

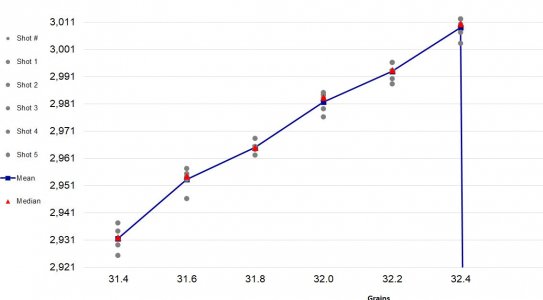

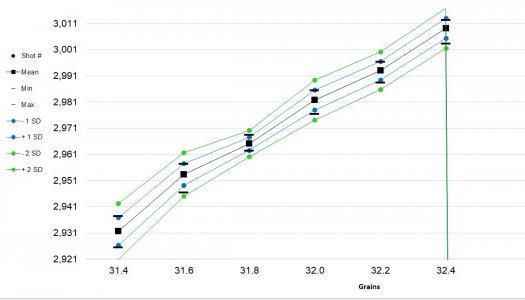

so i loaded up some 109gr hybrids from 31.4 to 32.4 in .2gr increments. recorded the data with the labradar and separate dots for each group. first time loading all the data into the v2 6.5guys excel sooooooooooooo here we go. i should have loaded more but i really do not want a HOT load for this rifle. i have to shoot 25+ shots in a relay and if i get a node down lower that works. not that where i was loading was low. DO NOT USE MY LOAD DATA THIS IS FOR ENTERTAINMENT ONLY.

so here is the raw data. lost a few shots due to the labradar not working, really need to get the barrel trigger so it does not nap while i am doing this. Loaded up 5 round at each weight and shot them pretty quick with a lil cool off time between shots.

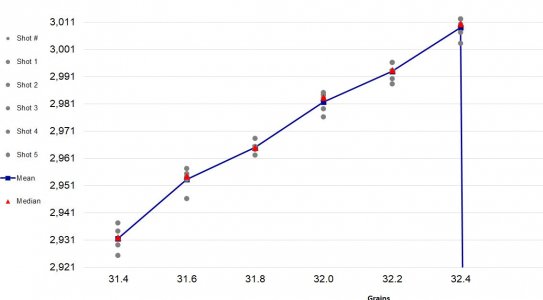

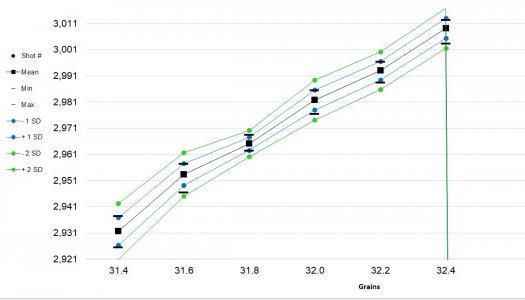

so from the data the 31.8 load seems to be happy! what do the groups say????

that is 5 shots in that group. for being shot off a bag not a bipod as the gun is setup for sling i am impressed. The other charge weights were all under 1" but some had vertical and some had horizontal dispersion. nothing to crazy but close to 1" on the worst group. Off a solid bipod or my joystick rest this rifle might have some .1s in her.

OK now for something new on the big girl the 7saum. I have been watching the trend with barrel tuners for a while and did not get my last tube threaded for one. Saw a guy shooting at the last match i was at with a DIY nut threaded on the barrel. got me thinking what could i slip on the barrel to make my own! turns out some guns already figured it out and shaft collars work just fine. Ran over to mcmaster carr and 10 bucks later i have a stainless shaft collar, picked up some nylon tipped set screws too while i was there. Problem one, the collar and barrel are the same diameter. Put some Emory cloth on a screwdiver and spun it up in the cordless. few quick passes and boom slip fit right on the money.

So the commercial tuners work by threading the barrel and screwing them on. as you turn it in they move down the barrel. small amounts make big changes here. so for this i used my micrometers with the depth gauge on the end that no one ever uses. The poky thing that sticks out as you open them is actually useful, go figure shot a bunch of depths with 3 shot groups. .844 seemed to be the magic spot found it about midway though the test. Retested at the end to confirm results. The wrong spots were very wrong. its kinda crazy how they work.

shot a bunch of depths with 3 shot groups. .844 seemed to be the magic spot found it about midway though the test. Retested at the end to confirm results. The wrong spots were very wrong. its kinda crazy how they work.

This is the group with the tuner in the wrong spot.

Back again to .844 and just like magic the groups shrink.

first up was the dasher, i had never done load development for it because it just shot good with the first load i tried and i had been neglecting it to be honest

so i loaded up some 109gr hybrids from 31.4 to 32.4 in .2gr increments. recorded the data with the labradar and separate dots for each group. first time loading all the data into the v2 6.5guys excel sooooooooooooo here we go. i should have loaded more but i really do not want a HOT load for this rifle. i have to shoot 25+ shots in a relay and if i get a node down lower that works. not that where i was loading was low. DO NOT USE MY LOAD DATA THIS IS FOR ENTERTAINMENT ONLY.

so here is the raw data. lost a few shots due to the labradar not working, really need to get the barrel trigger so it does not nap while i am doing this. Loaded up 5 round at each weight and shot them pretty quick with a lil cool off time between shots.

so from the data the 31.8 load seems to be happy! what do the groups say????

that is 5 shots in that group. for being shot off a bag not a bipod as the gun is setup for sling i am impressed. The other charge weights were all under 1" but some had vertical and some had horizontal dispersion. nothing to crazy but close to 1" on the worst group. Off a solid bipod or my joystick rest this rifle might have some .1s in her.

OK now for something new on the big girl the 7saum. I have been watching the trend with barrel tuners for a while and did not get my last tube threaded for one. Saw a guy shooting at the last match i was at with a DIY nut threaded on the barrel. got me thinking what could i slip on the barrel to make my own! turns out some guns already figured it out and shaft collars work just fine. Ran over to mcmaster carr and 10 bucks later i have a stainless shaft collar, picked up some nylon tipped set screws too while i was there. Problem one, the collar and barrel are the same diameter. Put some Emory cloth on a screwdiver and spun it up in the cordless. few quick passes and boom slip fit right on the money.

So the commercial tuners work by threading the barrel and screwing them on. as you turn it in they move down the barrel. small amounts make big changes here. so for this i used my micrometers with the depth gauge on the end that no one ever uses. The poky thing that sticks out as you open them is actually useful, go figure

This is the group with the tuner in the wrong spot.

Back again to .844 and just like magic the groups shrink.